|

||||

News & Events

|

|

Newsletter

|

|

Industrial Data Communication News and Techniques • Fall 2002, V3 #2 |

Reliable, Cost-effective & Expandable—

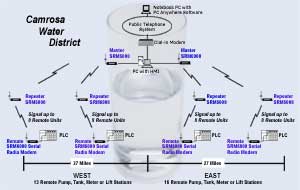

License-free wireless modems fill the bill for Camrosa Water District

The Data-Linc radio modem network:- Replaced expensive and unreliable leased phone lines

- Requires no FCC site license — system operates in the

902-928 license-free band - Accesses stations in difficult locations with Repeater mode modems

- Covered a 31 square mile area

- Communicates between HMI and PLCs at 19.2 Kbps

- Performs flawlessly despite RF noise interference from nearby locations

- Can expand to meet growing needs

|

|

Click on diagram for enlargement.

|

Prior to 1995, Camrosa was using a SCADA system for the remote monitoring and automated control of its 11 tanks, six pump stations, four sewer lift stations and 12 meter stations which are spread over a seven-mile radius. The system, which was installed and programmed by an RTU vendor, required the use of analog phone lines for communications among the remote locations - the charges for which totaled nearly $24,000 a year. Any time one of the phone lines malfunctioned, Camrosa was at the mercy of the phone company to repair the problem, waiting hours and sometimes days for service. In the meantime, Camrosa was also incurring significant labor charges from sending its own technicians to the remote sites to investigate the phone line problems.

Tony Stafford, superintendent of operations for Camrosa, explained that the district resolved to replace the existing SCADA installation with an HMI/PLC system to eliminate the monthly leased phone line charges, reduce labor charges and increase reliability. Just as importantly, the district also wanted to gain in-house control of the system.

In 1995, Camrosa began developing and installing its new PLC based HMI system, providing automated control at each tank and pump location with a PC-based HMI at their control center. Camrosa then installed two Data-Linc SRM6000 serial radio modems to serve as Masters at its central office, splitting its east and west remote locations between two serial ports on the master HMI PC to speed communications. Because the office is situated in a valley, Camrosa also installed four SRM6000 modems, which use Data-Linc's Smart SpectrumTM frequency hopping spread spectrum technology, to serve as Repeaters that negotiate the obstructions and maintain connectivity with all modems throughout the hilly terrain. Over the next year and a half, the District installed SRM6000s at each of its remote locations one at a time— systematically replacing each RTU and eliminating the phone lines.

Even though Camrosa Water District is located near a military base which generates a tremendous amount of RF noise, and the concern of some in the industry that the 902-928 MHz spread spectrum employed by the SRM6000 is becoming over saturated, Stafford said that Camrosa has never experienced any problems. He stated that he believes Camrosa has achieved all of its original objectives: “The new HMI has greatly enhanced our communication reliability and increased system operating efficiency. And we eliminated all phone line charges and reduced our labor costs.”

Camrosa’s new self-designed HMI also has some distinct advantages. If the master PC crashes, the PLCs are programmed to operate as stand-alone units. And through the use of PCAnywhere software, the District’s field technicians can dial into the HMI system from any laptop to monitor PLC status and radio communications online—without having to travel to the remote sites.

Download the complete three page pdf article (120 K) "Taking Back Control: Most common way to implement a SCADA system is to go outside, but is it the best way?" from ISA's Intech Magazine, July 2002.Data sheets for SRM6210E and the SRM6310E RF wireless Ethernet modems are available by visiting the Product section of our web site, contacting Data-Linc Group at

^ Top of Page ^

Data-Linc on the move— from Redmond to Bellevue |

||

|

Data-Linc Group Corporate Headquarters has departed Redmond, its location for over six years, for a larger facility just a few miles south in the city of Bellevue. The new building provides much needed space to further support our expanding customer base. Thanks to a great planning team there has been no break in service. Phone and fax numbers remain the same. As of September 3, 2002, find us at: |

|

|

Data-Linc Group Corporate Headquarters 3535 Factoria Blvd SE Suite 100 Bellevue, WA 98006 |

Phone: (425) 882-2206 Fax: (425) 867-0865 http://www.data-linc.com/ |

|

Trade Shows and Events Schedule—Be our guest and attend ISA for freeVisit our Trade Shows and Events page to see upcoming Data-Linc activities and to get directions on how to be our guest at ISA in October. |

||

Wireless and Ethernet —past, present and futureThe desire to monitor and control processes drives the growth of the market for data communication and data networking in industrial applications. But to get the data from point A to point B, there is a certain price to pay— money and time. Wireless data transmission has become a popular and cost effective alternative to cable installation (intra-plant), and phone line usage (inter-plant).The industry standard for the past number of years has been RS232 or RS485/422 connections that provided a serial interface between components, such as PLCs (programmable logic controllers), RTUs (remote terminal units) and HMI (human machine interface) or PCs. These adopted standards have not only reduced the cost of a network’s infrastructure (components need not be custom made) but also support operating within defined rules and protocols allowing the different components to interface and interact predictably. Industrial PLC and automation networks are quickly migrating to Ethernet, and away from proprietary serial protocols. This article looks at applying wireless technology to Ethernet networks because of the significant installation cost of in-plant wiring (as much as $20 to $200 per foot) or high cost of leasing phone lines for plant-to-plant networks. This four part series looks at the history of wireless, advantages and disadvantages of different radio transmission standards, wireless system implementation considerations and real-life application examples. Wireless History— Where we’ve come fromWireless communication is not new. Whether one credits Stubblefield— "wireless telephone" in 1892— or Marconi— "syntonic wireless telegraphy" in 1901— as the inventor of wireless technology, airwaves have carried data for over 100 years. Radio telegraphy was the pioneer application of wireless transmission followed by broadcast radio, RADAR, TV and then satellite. The mobility of the Handie Talkie in WWII gave rise to recognition of the potential for mobile voice communication and by the early 60s, sparked the era of commercialized wireless voice transmission. Since then many wireless techniques and protocols have evolved, developed and been deployed for military/government, commercial and industrial applications. Because of the increase in popularity of wireless communication, radio frequency (RF) bands became crowded. A need developed for radio band regulation to avoid communication overload, interference and chaos. Major RF organizations world wide, e.g. the FCC (Federal Communications Commission in the U.S.) and the ETSI (Europe), regulated the RF bands in the individual countries. As a result licensed bands worldwide became very expensive. In response to demand, government regulatory bodies assigned frequencies for data communication with no license fee— first the CB (Citizens Band for Amateur Radio operators) and later the ISM-band (industrial, scientific, medical). ^ Top of Page ^ Wireless Technology Today- Where we areWireless data transmission has become the medium of choice. The ISM bands for industrial applications are the 400MHz (Europe), 900 MHz (USA), 2.4 GHz and 5 GHz range (worldwide). The bandwidths in the ISM bands vary from 5MHz to 80MHz and more. Because radio modems, whether direct sequence or frequency hopping, do not have wires that need installation and then replacement when they wear out, wireless is cost effective- reduced down time, reduced replacement cost, no recurring leased line fees. Additionally, wireless data transmission can cover distances not practical with most wire solutions and can be installed where wire would be impossible. There are two basic types of wireless technologies – radio frequency (RF) and light based systems. RF includes a wide variety of technologies and services including Narrow Band, Spread Spectrum, Cellular, Broadband Microwave and Satellite. Some RF technologies require a government license (e.g. narrow band), some are license-free (spread spectrum) and others are subscription service based (cellular, satellite). Light based systems include Infrared and Laser Beam and are limited to short range applications. Depending upon the application, different modulations within each of these are used to maximize the performance and the quality of the wireless data transmission. Two main factors— speed/data rate and distance/range— define the performance of data communication. Figure 1 shows the different wireless technologies/ modulations in ideal conditions— data rate, expressed as million bits per second (Mbps), and range, reported in meters with LOS (line-of-site). It is important to consider the key elements of an industrial wireless solution:

Ethernet packets (typically TCP/IP) are not inherently designed to optimize available bandwidth. Therefore, wireless technologies that offer relatively slow data rates are not a good match for Ethernet applications. Narrow band UHF/VHF and cellular CDMA are limited greatly by data rate because of slim bandwidth. DSSS and FHSS technologies operating in the ISM bands offer acceptable data rates for Ethernet. Today, they are the predominant wireless technologies for Ethernet. For industrial applications, FHSS is often preferred because of its interference immunity and long-range capabilities. However, data rate is limited to around 100 Kbps. Fortunately that is quite acceptable for most SCADA, RTU and HMI applications today. The Future— Where we’re goingIndustrial wireless Ethernet applications will demand greater bandwidth as communication needs increase. This is driven by applications such as data collection for statistical analysis (high sampling rates), wireless sensor-level connectivity, multi-media (e.g. video) and real time control. New wireless technologies are emerging that promise significant increases in data rate while retaining long range and interference immunity. While in theory, these technologies (e.g. MDMA, UWB) offer revolutionary data rates and range; their actual performance, deployment (legality) and commercial availability are unclear. Fortunately, recent advances in frequency hopping spread spectrum (FHSS) offer hope for industrial-rugged transmission at considerably higher data rates. Advanced FHSS may fill an immediate "hole" in the long-range industrial wireless Ethernet market using the existing ISM bands. In our next edition, Part IIComparing wireless Ethernet technologies for Industrial NetworksPart II of our continuing series of wireless Ethernet articles will focus on existing and emerging RF technologies and their appropriateness for industrial networking.

^ Top of Page ^

|

|

| High performance, superior quality modems for a broad range of industrial applications.

Robust, reliable data communication, even in high interference environments. License-free radio modems— no FCC/DOC site license required. Industrial grade modems and networking products include:

• Wireless Ethernet • Dial-up/Leased Line • Dedicated Wire FSK • Fiber optic Modems • Multi-port Modem Systems • Analog/Discrete Signal Muxes • Comprehensive Communication System |

|

||

| Address | 3535 Factoria Blvd. SE Suite 100 Bellevue, WA 98006 |

||

| Telephone | (425) 882-2206 | ||

| Fax | (425) 867-0865 | ||

| info@data-linc.com | |||

| Web site | www.data-linc.com | ||

|

©2002, Data-Linc Group. All rights reserved. |

|||

wireless frequency hopping technology |

|||

|

|||

^ Top of Page ^

Products

Features & Benefits | Focus Item | Product Selection Guides | Catalog | PDF Library | Order Information | FAQ

Tech Resources

Engineering Specifications | Articles & Technical Papers | Installation Information

Partners

GE Fanuc | Omron | Rockwell Automation | Schneider Electric | Siemens | Technology Partners

Industries

Security | and other industry application notes and diagrams

Sales Channels

Distributors | System Integrators | OEMs

News

Tradeshows and Events | Press Releases | Newsletters

About Us

Overview | Jobs/Employment | Office Locations/Contact Information

![]() Chinese

Chinese![]() Español

Español

![]()

Data-Linc Group

3535 Factoria Blvd. SE, Suite 100 • Bellevue, WA 98006 USA

Tel (425) 882-2206 • Fax (425) 867-0865 •

© 1996-2009 Data-Linc Group. All rights reserved.

| 071203 |