|

|

|

||||

|

||||

|

News & Events

|

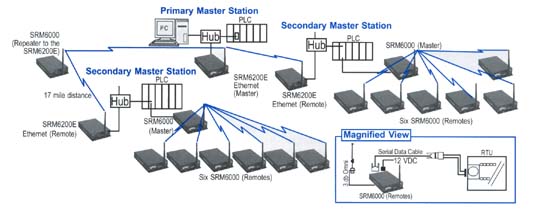

Water Authority Improves The Situation Running at 300 baud, the system was extremely slow and data acquisition was time-consuming. Data accuracy was usually in question as it was not received in real time. The Problem The Solution Data-Linc Group offered pre-configuration of equipment, including modem, data cables, antennas and coaxial cable. Data-Linc Group performed presale engineering analysis and technical application support for the communications network. This would ensure a quick and trouble-free integration with the PLC. Data-Linc Group also offered VVWRA additional technical support and a quick turn around on products. VVWRA purchased 15 SRM6000 wireless radio modems (one Repeater, two Masters and 12 remotes), and three SRM6200E wireless Ethernet radio modems (one Master and two remotes). The units arrived at VVWRA pre-configured. The Results "I have a unit I'm on-line with right now, said Bruce Correia, application engineer at Victor Valley Water Reclamation Authority. "It's just as though it's in the office with me." Correia further stated that he's recommended Data-Linc Group to others in the industry. "Data-Linc Group made installing the new system easy. About the only thing they didn't do was hand deliver and install the modems." Gray Skies are Gonna Clear Up The system involved a Master PLC, located in the maintenance center, communicating to two remote PLCs at the end of the runways. These two PLCs controlled the lights in the Stop Bar system. The primary communications were via fiber optic modem with Data-Linc Group SRM6000 radio modems as a backup communications path. By mid-October, everything but the fiber optic portion of the system was up and running. Testing was under way using backup communications until the fiber optic system could be completed. On October 21, Data-Linc Group received an urgent phone call from Honeywell requesting us to contact the Port of Seattle concerning a problem they were having with the Stop Bar system.

Randy met with Erlin, a maintenance technician at SeaTac Airport. He received a briefing on how the system worked and what was happening when the system would fail. Afterwards, they went to the site of the remote processor. This is the location where communications appeared to be failing. The system at the remote processor site appeared to be working. It was then Randy learned that the only time the system would fail was in the early hours of the morning. The timing of the failure was strange. After further investigation, they discovered the communications cable between the PLC and the SRM6000 radio modem had slipped onto high voltage power cables in the cabinet. These cables were part of the battery charging system for the lights, and at night, carried up to 3000VDC. It was surmised that noise from the high voltage cables was being induced into the modem through the data cable. This would overwhelm the buffer in the modem since it would not be given a chance to recover (no noise). When this occurred, the modem would go off-line, rather than passing the noise to the Master modem. The data cable was properly repositioned and secured. The SRM6000 modem was replaced in the event the other modem suffered any damage from the high voltage. Erlin and Randy then inspected the other remote location and determined there were no problems. While commuting the next morning, Randy listened to a news report stating that SeaTac Airport was experiencing heavy delays due to very dense fog. The airport was only able to operate one runway. When he arrived, Randy telephoned the airport maintenance center and related the news report and his concern that perhaps something was overlooked. The maintenance center reported that the airport was open because he and Erlin had fixed the problem. The Stop Bar system was up and running, allowing one runway to remain operational - even in the thick fog. If the system had not been repaired the day before, air traffic would have been stacking up all the way to the East Coast. Later, testing was done on the original modem and no damage was found. SeaTac maintenance center has since reported that no further problems have occurred. The fiber optic system has been completed and is now operational. Confidence in the entire system is at an all time high because backup communications worked. Data-Linc Group proved it. Walk and Talk:

As a device moves, obstructions may impede the signal. It is ideal to place the antennas where obstructions are eliminated; however, this can be impossible. Data-Linc Group's Smart Spectrum™ technology has been field proven to communicate through (or around) concrete, drywall and, in some cases, metal. If the obstruction is brief (such as a steel beam encountered while a crane moves), communication will continue. The 902-928 MHz band has proven more robust in applications with obstructions compared to the 2.4-2.4835 GHz band (Data-Linc offers both). The lower the frequency, the better the signal bounces around obstacles. Because each application is unique, a field test of the radio modems is the best way to ensure feasibility and reliable communication. Communications within buildings can cause a high magnitude of multi-path reflections. This occurs where the radio frequency (RF) transmission signal bounces off numerous structures and is detected at the modem's receiver. This form of interference can play havoc with direct-sequence radio systems because the reflected signal confuses the receiver. The problem widens when the transmitter moves because the reflection paths change. Smart Spectrum's frequency hopping transmission method is much more tolerant of multi-path reflections than direct sequence.

Data-Linc's Smart Spectrum radio modems are ideal for applications involving moving equipment. The modems are field proven to operate in applications such as crane wiring harness replacement, automatic guided vehicles, transportation applications and communication to PLCs mounted on spinning platforms. Of course, the best approach is to thoroughly test the technology in the actual environment. Off the Wire The Southern Alberta Institute of Technology (SAIT) contacted Data-Linc Group regarding the possibility of donating radio modems for their PLC lab. During the day, students from their Electrical, Petroleum and Instrumentation programs are taught the latest automation hardware and software. Evening courses are offered to engineers, consultants, designers and maintenance personnel in the oil and gas industries.

Without hesitation, Data-Linc Group donated two SRM6000 radio modems. Upon receipt, Peter Leliveld, Centre Coordinator, wrote us. "I would like to acknowledge your generous donation to our PLC lab....I would like to reinforce just how grateful we are for your support and contributions." We were just proud to help. New Year, New Name

|

||||||||||||

| ^ Top of Page ^ | ||

|

|

||

| Products |

Features & Benefits | Focus Item | Product Selection Guides | Catalog | PDF Library | Order Information | FAQ | |

| Tech Resources |

Engineering Specifications | Articles & Technical Papers | Installation Information | |

| Partners |

GE Fanuc | Omron | Rockwell Automation | Schneider Electric | Siemens | Technology Partners | |

| Industries |

Security | Traffic | and other industry application notes and diagrams | |

| Sales Channels |

Distributors | System Integrators | OEMs | |

| News |

Tradeshows and Events | Press Releases | Newsletters | |

| About Us |

Overview | Jobs/Employment | Office Locations/Contact Information | |

|

|

||

| © 1996-2008 Data-Linc Group. All rights reserved. | ||

| 071203 |