|

|

||||||

|

||||||

Industries

Industries: Oil and GasDecreasing foreign oil dependency byMilking Marginal Oil Wells |

|

||||||||||||||||||||||||

| By Karen Perlbachs, MarCom Manager, Data-Linc Group and Charles Ice, President/Founder Fifo Technologies, Inc. |

|||||||||||||||||||||||||

| Abstract- Fifo Technologies’ extraction process economically accesses untapped crude oil remaining in the ground in abandoned stripper wells. Reynold’s Electric specified Data-Linc Group wireless Ethernet modems and Allen-Bradley MicroLogix PLCs as the key components to give operators real-time central control for around-the-clock monitoring of pumps installed at various remote locations. With over 300 initial installations, Fifo is "Bringing back American energy independence one well at a time." (Download the four page 4.7 MB pdf print quality version of this article.) |

|||||||||||||||||||||||||

|

Decreasing Oil Reserves, Unstable Sources, Volatile Prices In 2005, a US Department of Energy report estimated that 110 million barrels of crude oil remain in the ground in wells where extraction produced 10 barrels a day or less. Approximately 400,000 of these marginal “stripper wells” produce nearly one million barrels of oil per day— 19% of U. S. production. About 142,000 stripper wells were plugged and abandoned from 1994 to 2003, costing the United States in excess of $3.8 billion in lost oil revenue at the Energy Information Administration’s reported 2004 average world oil price. Although the well closure trend has slowed, primarily due to the high oil prices of the past several years, reactivating these wells remains very expensive. The amount of oil remaining in marginal stripper wells may seem relatively small when viewed individually, but taken collectively it is a resource wellspring. Large numbers of retired oil wells across the U.S. have been capped, with the equipment disassembled and redeployed. The volatile price of oil and the unstable oil markets have made it essential to utilize these resources in order to access otherwise lost oil revenue thereby decreasing dependency on foreign oil. From Expensive Conventional Pumps to Low-cost Lift System New-on-the-scene in 2006, Charles Ice, founder and President of Fifo Technologies, Inc., conceptualized, developed and produced an artificial lift that could replace the expensive traditional pumping technology for extracting oil from stripper wells. His lift offered the oil industry a system with a low enough capital outlay for purchase, installation and maintenance that it could be economically feasible for oil companies to convert dormant wells into oil producers.

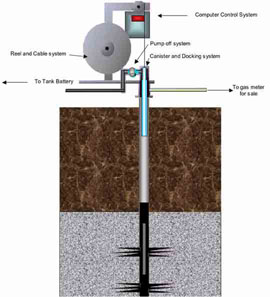

The Fifo F1000 system provides a low cost, state of the art solution for marginally producing oil wells in the 1/2 to 3 barrels per day category at a depth of 3000 feet. Additionally, the F1000 has no “down hole” parts, it therefore requires no special equipment for maintenance or repair. From No Real-time Monitoring to Automated Continuous Monitoring, Control and Reporting Unlike the conventional or jack pump that require on-site maintenance and monitoring, the F1000 has the capability to remotely log and report data as well as monitor and control production and operation, significantly lowering extraction costs by 65% to 80% over conventional pumping methods. For the data transfer module of his system, Ice, selected the robust, long-range wireless Ethernet modem from Data-Linc Group and worked with The Reynolds Company (TRC of Dallas, Texas), the local distributor for Data-Linc products. For the SCADA (Supervisory Control and Data Acquisition) system component, Reynolds recommended the Allen-Bradley MicroLogix 1100. Fifo , Data-Linc Group and Reynolds’ cooperative effort resulted in a network design that seamlessly interfaced pump, data-communication equipment and PLC (Programmable Logic Controller) into a reliable, economical network solution for tapping the thousands of abandoned stripper wells. Each Fifo unit includes the F1000 lift system, an Allen-Bradley MicroLogix 1100 and a Data-Linc SRM Ethernet radio modem. The MicroLogix is a “smart” component that can be programmed to monitor and control what is happening at the Remote station and report that data to central control.

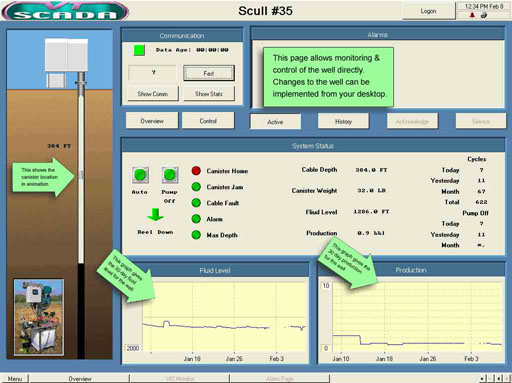

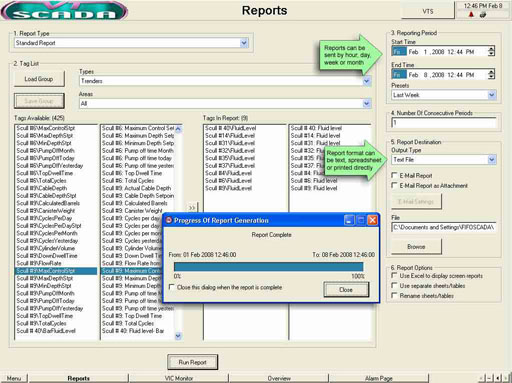

From Limited On-site Checks to Remote, Real-time Monitoring, Control and Reporting Data-Linc’s 900 SRM MHz wireless Ethernet modem transfers the data between the MicroLogix at the well site and the SRM modem connected to the PC at the control center for real-time monitoring and control with the capacity to program the MicroLogix 1100 PLCs anywhere on the network. This means, from any PC anywhere, the Fifo system can continuously monitor and control pump activity—for continuous fluid level monitoring, daily well production records and well-gas capture for delivery to flow-lines— without special software or costly communication systems (See Figure 2). Fifo’s F1000 system provides critical communication but requires no cables between well pumps and storage tanks and thus avoids expensive trenching and the recurring cost of leased lines. Additionally, the SCADA software provides reports and electronic data logs associated with the production of the wells— well bore fluid level, number cycles vs. number of pump offs, current set point and current oil production, etc., all of which may be forwarded to a secure web site. These features allow those involved or responsible for the project to have access to production records and operational data as needed and in real-time. The various reports can be down loaded into spreadsheets and printed or viewed online from any location. (See Figure 3.)

|

|||||||||||||||||||||||||

|

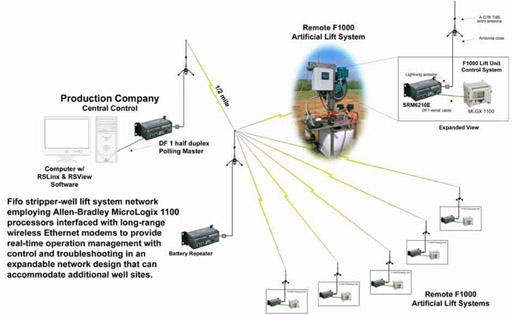

From High-cost Independent Sites With On-sight Management to Lowcost Networked Sites with 7/24/365 Management From one central control station, the combination of the SRM modems interfaced with the MicroLogix PLCs in a point-to-multipoint network makes possible around-the-clock management of the pumps installed at multiple, diversely remote sites, employing wireless data transfer from lift stations to the production office. Unlike conventional pumping systems, operators receive real-time data and immediate notification of shutdowns and alarms. They can, therefore, respond quickly, reducing downtime, increasing production time and positively impacting ROI (return on investment). Fifo’s system offers users a vast improvement over conventional, unmonitored wells where an inactive pump system can lay dormant for days, weeks or even months due to undetected problems. Data-Linc’s long-range SRM Ethernet modems provide the required range and broad bandwidth that accommodates the powerful MicroLogix 1100 through its Ethernet port providing a robust, reliable network (See Figure 4.)

In the F1000 units, each Remote SRM Wireless Ethernet modem is connected to a MicroLogix 1100 PLC that controls and monitors the Fifo Strip Well System. Utilizing the Data-Linc SRM modem’s capability in the network allows Fifo the advantages of not only continuous monitoring, but also real-time troubleshooting and up-grade capability as well. The server at the production company can communicate to the end of the farthest strip-well system for every location. Point-to-multipoint communication occurs from the individual customer’s Master to each uniquely identified Remote modem via its IP address. The Master is connected to a computer running Rockwell’s RSLinx software allowing the network direct, virtually real-time linkage to the farthest stripper well in the system and the individual customer’s server, the production company’s server or even at the level of Fifo’s secure dedicated server. Monitoring the system’s associated storage tank battery fluid level is straightforward. If the battery is near a pumping unit—within approximately 200 feet, cable could also be the preferred method for relaying the fluid level data to the pumping unit’s modem that then transmits the information to the Master. If the tank battery is beyond 200 feet from a pump, an SRM Ethernet radio modem in Repeater/Remote mode can transfer the data to the Master and also function as a Repeater for the pumping unit if required. The SCADA system allows remote monitoring and control of all the wells and minimizes the need for repairmen to deploy to remote locations. Repair and maintenance responsibilities change from visiting all sites to look for operational problems, to response to specified alerts or problems, saving worker time, site downtime and transportation costs.

Conclusion Download the 4 page print quality pdf (file size 4.3MB) version of this article . |

|||||||||||||||||||||||||

About DATA-LINC GROUP

Since 1988, Data-Linc Group has provided robust communication solutions for industrial automation and instrumentation systems and manufactures the world’s broadest line of industrial wireless and wire modems. Data-Linc Group, an alliance partner with most major PLC manufacturers, provides expert technical support and communications consultation. Data-Linc’s industry proven RF technology has been successfully implemented globally in all major industries including oil and gas, water/wastewater, metals and mining, automotive, manufacturing/packaging, materials handling, pulp and paper, utilities, transportation and security. With its line of wireless modems for the European Union, Data-Linc’s products and support are available worldwide. Data-Linc provides field proven product performance and industrial grade support. For assistance regarding your project or for details about the capabilities of the powerful LincView OPC diagnostic RF network management software and its appropriateness for your specific application, please contact Data-Linc using phone or fax information below or email F-1000@data-linc.com.

About Fifo Technologies, Inc.

Fifo Technologies, Inc., located in Fort Worth, Texas, provides new, innovative technologies to the marginal or “stripper” oil well industry. Fifo accomplishes this as a result of decades of engineering and manufacturing experience using state of the art materials and components. Fifo Technologies is committed to the industry and to its customers to provide the best and most profitable solutions to the marginal oil well business. For more information please visit www.fifoenergy.com, call 817-330-0383 or email oil@fifoenergy.com.

About The Reynolds Company

The Reynolds Company is an independently owned and operated

wholesale distributor headquartered in Dallas, Texas, with sixteen

warehouses and seventeen sales offi ces covering North Texas and

the Gulf Coast, including four locations in Southern Louisiana. With

over 60 years of experience, Reynolds is a market leader in delivering

value-added services and gaining long-term customer loyalty. Visit

Reynolds on the web at http://reynoldsonline.com, contact Corporate

Headquarters via 817-626-3636 or email ContractorDivision-

FortWorth@reynco.com

About Rockwell Automation

Rockwell Automation is a leading global provider of automation, power, control, and information systems and services that help manufacturers achieve a competitive advantage in their businesses. Headquartered in Milwaukee, Wisconsin, the company employs about 21,000 people serving customers in more than 80 countries.

For assistance regarding your project or for details about the capabilities of the powerful LincView OPC diagnostic RF network management software and its appropriateness for your specific application, please contact Data-Linc .

| ^ Top of Page ^ | ||

|

|

||

| Products |

Features & Benefits | Focus Item | Product Selection Guides | Catalog | PDF Library | Order Information | FAQ | |

| Tech Resources |

Engineering Specifications | Articles & Technical Papers | Installation Information | |

| Partners |

GE Fanuc | Omron | Rockwell Automation | Schneider Electric | Siemens | Technology Partners | |

| Industries |

Security | and other industry application notes and diagrams | |

| Sales Channels |

Distributors | System Integrators | OEMs | |

| News |

Tradeshows and Events | Press Releases | Newsletters | |

| About Us |

Overview | Jobs/Employment | Office Locations/Contact Information | |

|

|

||

| © 1996-2009 Data-Linc Group. All rights reserved. | ||