|

|

||||

|

||||

|

|

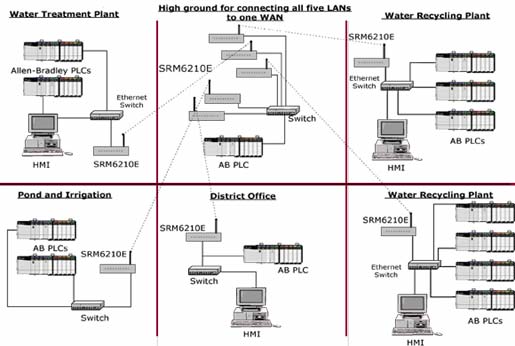

Articles and Technical PapersExpanding legacy SCADA system to meet growing demandsAuthor: Confronting growth and data accessibility demands in Utility companies can involve exorbitant system upgrade costs. Lakeway Municipal Utility District in Austin, TX chose to incorporate wireless Ethernet modems to economically expand their legacy system and close their data acquisition gap. Upgrading a utility SCADA (Supervisory Control and Data Acquisition) system can be a daunting project. Several factors influence the decision process, the least of which is cost. It is not only replacement expenditures but there is also the consideration of future scalability and anticipation of unknown issues. Lakeway MUD is located west of Austin on Lake Travis, established in 1972. It is a Water, Wastewater and Water Reuse facility producing drinking water and providing wastewater collection, treatment and total water recycling for a community of 10,000. They began their SCADA system in 1995. It consisted of one local operator workstation site and one remote Programmable Logic Controller (PLC) site. Local and remote sites were connected by dedicated full duplex telephone modems. The SCADA system’s primary task was collecting real-time data on weather conditions, calculation of irrigation application rates for disposal of excess reuse water and data used in Research Demonstration Studies. As the community water needs grew so did Lakeway MUD. Expansion took place in 1996,1998, 2000 and 2001. In 1996 they expanded their SCADA system to include an operator workstation at the water production plant. The operator workstation had the primary function of interfacing with the PLC at the plant site and with a remote PLC at a raw water pump barge. In 1998, the system was expanded again to include two booster stations and establish communications with the original operator workstation, thus providing two workstations. In 2000, a new wastewater system consisting of four remote sites for collection, treatment, storage, pumping and delivery to reuse customers was installed. And, in 2001 expansion began on another wastewater system. The end result of the 5 year expansion created a system of 4 separate networks, -26 PLCS and 6 PCs at four operator interface sites. The system communications continued over leased lines. The PLCs controlled all processes and required significant operator interaction elevating labor costs and error margin. Lakeway management wanted to integrate all of the remote PLCs into one communications system so that operators could all have similar access to the system. Several goals were identified- all data accessible at all PCs, delivery of operations data to Operators, maintain or improve system speed, provision for future expansion and independence from outside vendors (Telco company). Unfortunately, constraints in the communication protocol of the existing system selected back in 1995 would not allow for this and restricted expansion in other areas as well. Consultations with suppliers led the District to evaluate their alternatives, including a full system replacement. The resulting decision was to install an Ethernet network with a few key PLCs and design a strategic communication infrastructure using wireless Ethernet radio modems on the license-free 902- 928 MHz ISM band. Data-Linc Group in Bellevue, WA, was chosen to supply the communication link. Data-Linc Group provided the wireless Ethernet radio modems and radio frequency expertise needed to bring the system architecture to fruition. The Ethernet connection and factory configuration fit perfectly with Lakeway's situation and modem installation was low effort. The resulting network consists of several point-to-point and point-to-multipoint radio links between the key PLCs. The Ethernet radios function as an Ethernet bridge and do not require a network IP address. Most of the remote sites communicate through a group of 5 master radios connected into an Ethernet Switch, thus providing seamless links. Several of the remote sites have the PLC and radio connected together with an Ethernet Hub. This provides user ability to plug a lap top computer into the hub and become part of the network. The system design successfully connected all five LANs to one WAN accomplishing the goal of communications back to the district office and allowed Lakeway to optimize their internal management software. The final solution benefits are the security of Ethernet 802.3 network standards, smart learning wireless modem bridge (Smart SpectrumTM frequency hopping), transparent multipoint functionality and the reliability of the 902- 928 MHz band. The wireless solution also avoided miles of cable installation and the volatility of leased line communications. Lakeway continues to be extremely pleased with their solution and the role wireless Ethernet modems have played. “The modems are easy to install and are extremely reliable, “ says Richard Eason, General Manager of Lakeway MUD. “There has been no problems since start up.” The Lakeway MUD SCADA expansion was a success and the implementation of these changes allowed them to keep up with growing demands. They were able to retain much of the old network, restricting costs and disruption, while realizing all of their business goals. Lakeway Municipal Utility Department SRM6210E Ethernet radio modem network

Go to the Allen-Bradley Diagrams section to see a larger version of this diagram as well as diagrams of various Data-Linc Group modems interfaced with Allen-Bradley automation equipment for peer-to-peer, multi-drop, multi-point and SCADA applications. Also see other Industrial Applications. |

||

| ^ Top of Page ^ | ||

|

|

||

| Products |

Features & Benefits | Focus Item | Product Selection Guides | Catalog | PDF Library | Order Information | |

| Tech Resources |

Engineering Specifications | Articles & Technical Papers | Installation Information | |

| Partners |

GE Fanuc | Omron | Rockwell Automation | Schneider Electric | Siemens | Technology Partners | |

| Industries |

Security | Traffic | and other industry application notes and diagrams | |

| Sales Channels |

Distributors | System Integrators | OEMs | |

| News |

Tradeshows and Events | Press Releases | Newsletters | |

| About Us |

Overview | Jobs/Employment | Office Locations/Contact Information | |

|

|

||

| © 1996-2015 Data-Linc Group. All rights reserved. | ||

| 071025 |